.webp)

Coordinate Measuring Machines

Mitutoyo Coordinate Measuring Machines (CMMs) set the global standard for accuracy, speed and reliability in dimensional inspection. With advanced probing technologies, rigid machine structures and powerful analysis software, these systems provide manufacturers with the confidence to verify even the most complex parts against the tightest tolerances. Whether you’re inspecting aerospace components, medical devices or high-volume automotive parts, Mitutoyo CMMs deliver the clarity and repeatability needed to turn quality assurance into a true competitive advantage.

Quick Contact Links

Sales Support

1-888-MITUTOYO

Get pricing and availability

Technical Support

1-888-MITUTOYO

Monday-Friday 8am-5pm EST

Request Information

Get detailed product

specifications & pricing

Find Distributor

Locate authorized distributors

near you

Coordinate Measuring Machines

Coordinate Measuring Machines

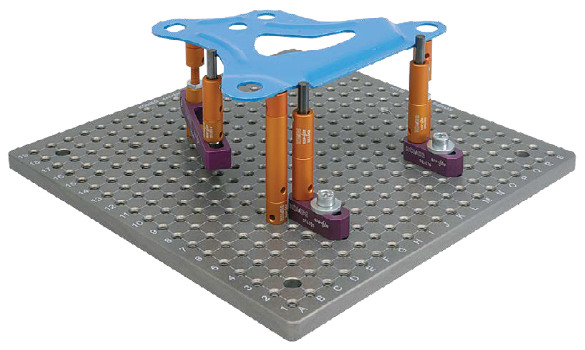

The unmatched precision and reliability of Mitutoyo CMMs help manufacturers in every industry achieve faster, more accurate inspection and quality assurance. Models such as the MiSTAR Series, built for shop-floor durability, and the versatile CRYSTA-Apex Series that is engineered for high-accuracy measurements, showcase Mitutoyo’s ability to deliver performance that fits both demanding environments and advanced applications. Supporting up to five-axis measuring and three-dimensional tolerances in both contact and non-contact modes, Mitutoyo CMMs integrate seamlessly into workflows for factory intelligence and advanced manufacturing. Mitutoyo continues to push CMM technology forward, providing the precision, speed and reliability that keep your quality standards a step ahead.

Software and Probes

Accessories

Coordinate Measuring Machines

Software and Probes

Accessories

Industry-Leading Precision Tools

For over 90 years, Mitutoyo has set the global standard for precision measurement. Our comprehensive portfolio delivers the accuracy, reliability, and innovation that quality-conscious manufacturers depend on.

Ask Mitutoyo

Frequently Asked Questions

Have Question? We are here to help

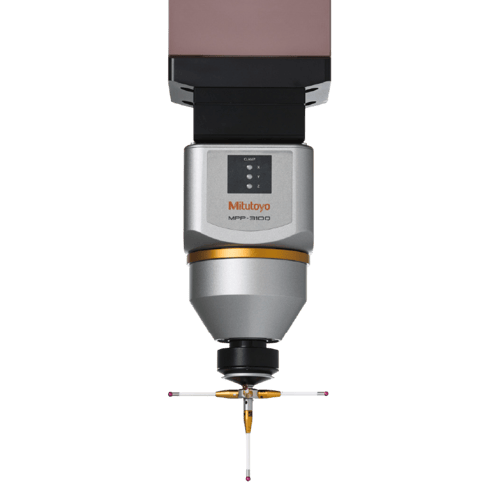

What types of probes are available for a Mitutoyo CMM?

Mitutoyo CMMs are compatible with a variety of probing systems to suit different applications. The most common type is a touch-trigger probe, which registers a point when the stylus makes physical contact with the part. Other options include active scanning probes, which drag across the surface to collect thousands of points, and 5-axis probes that can move and rotate to measure complex geometries faster. Additionally, Mitutoyo offers non-contact probes, such as laser or optical sensors, for delicate or soft materials.

What is the Mitutoyo MCOSMOS software and what are its main functions?

MCOSMOS is a comprehensive metrology software suite. Its main function is to control the CMM and process the measurement data. It allows operators to create and run part programs, perform geometric calculations, analyze data with statistical process control (SPC) tools, and generate measurement reports. It supports various modules, including GEOPAK for basic geometry, CAT-1000S for CAD-based programming and surface analysis, and MiCAT Planner for automated program generation from 3D models with GD&T information.

Can I use a Mitutoyo CMM for both contact and non-contact measurements?

Yes, many modern Mitutoyo CMMs are designed to be multi-sensor platforms. This means you can use a touch-trigger probe for traditional contact measurements and then switch to a laser or vision probe for non-contact measurements of features that are difficult to access or for parts that are too delicate to touch. This versatility allows a single CMM to be used for a wide range of applications and part types.

How can I get a service or repair for my Mitutoyo CMM?

Mitutoyo offers comprehensive service and support to keep your CMM running at peak performance. You can contact our service department to schedule routine maintenance, annual calibrations, or emergency repairs. Their certified technicians are trained to service all models and can provide on-site support to minimize downtime.

Complete Section L

Complete Catalog US-1006

For all your Coordinate Measuring Machine needs

Comprehensive Services & Support

Training & Education

Enhanced Services

Mitutoyo offers extensive hands-on expertise with contract inspection and contract part programming services to optimize your production and quality control processes. These Enhanced Services are idea for boosting productivity or adding expert help for projects large and small.

Field Service

Whether you need immediate repair service for critical tools or A2LA Accredited calibration that’s traceable to NIST on your measuring instruments, highly skilled Mitutoyo technicians provide fast, accurate and dependable service to keep you measuring with confidence.

E-Learning

Learn at your own pace! Enroll in Mitutoyo eLearning and get extensive hands-on training on our tools and software, including MCOSMOS C1 (STC-100 v5) and MCOSMOS-M1 (STC-101) courses.

Quality You Can Trust

Expert Support

Technical specialists available to help with your needs at a momentss notice.

ISO 17025 Accredited

Our calibration laboratories meet the highest international standards.

Industry-Leading Warranty

Comprehensive coverage backed by our commitment to quality.

NIST Traceability

All calibrations are traceable to national standards.

Ready to Upgrade Your Measurement Capabilities?

Connect with our experts to find the perfect small tools solution for your needs.