.webp)

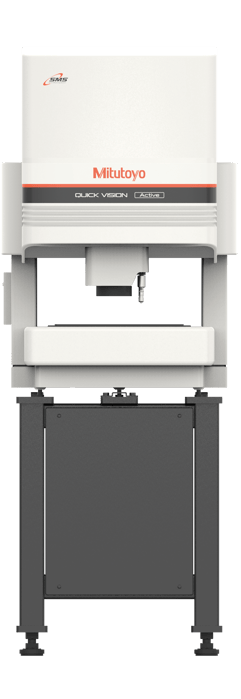

Vision Measuring Systems

Mitutoyo Vision Measuring Machines combine advanced optics, high-resolution cameras and intuitive software to deliver fast, non-contact dimensional inspection of every detail with absolute clarity and precision. From small, intricate components to larger assemblies, these systems capture complex measurements that traditional methods just can’t accomplish. Backed by the global reputation for quality, precision and innovation, Mitutoyo Vision Measuring Machines help manufacturers streamline quality control and ensure every part meets exact specifications.

Quick Contact Links

Sales Support

1-888-MITUTOYO

Get pricing and availability

Technical Support

1-888-MITUTOYO

Monday-Friday 8am-5pm EST

Request Information

Get detailed product

specifications & pricing

Find Distributor

Locate authorized distributors

near you

Vision Measuring Systems

Mitutoyo Vision Measuring Machines are built with high-end components for lasting performance, delivering non-contact inspection solutions with exceptional accuracy, durability and value. Available in a wide range of sizes, speeds, resolutions and sensor configurations, Mitutoyo vision systems adapt to virtually any application or budget. At the forefront of this lineup, the new QM-Fit showcases the commitment of Mitutoyo to continually innovate vision systems to deliver speed, quality, advanced capabilities and better usability while maintaining the precision you require and trust from Mitutoyo.

Vision Measuring Systems

Industry-Leading Precision Tools

For over 90 years, Mitutoyo has set the global standard for precision measurement. Our comprehensive portfolio delivers the accuracy, reliability, and innovation that quality-conscious manufacturers depend on.

Ask Mitutoyo

Frequently Asked Questions

Have Question? We are here to help

What types of parts can I measure with a Vision Measuring Machine?

Our machines are used to measure a vast range of parts across industries, including:

-

Electronics: Printed circuit boards (PCBs), connectors, semiconductor wafers.

-

Plastics & Rubber: O-rings, molded components, gaskets.

-

Medical Devices: Stents, surgical tools, implants.

-

Aerospace & Automotive: Small precision components, stampings.

-

General Manufacturing: Gears, cutting tools, metal stampings, and more.

What is the difference between manual and automated (CNC) systems?

Manual Systems: You manually move the stage and focus the camera on the part's features. These systems are perfect for one-off inspections, R&D, and low-volume applications.

Automated (CNC) Systems: The machine automatically moves the stage, adjusts the focus, and runs pre-programmed inspection routines. This automation is essential for high-volume production, where you need to measure hundreds or thousands of identical parts quickly and repeatedly.

What kind of lighting options are available?

Lighting is crucial for accurate edge detection. Our systems offer various advanced lighting options, including:

-

Coaxial lighting: Provides uniform light from the same axis as the lens, ideal for shiny or reflective surfaces.

-

Ring lighting: Illuminates the part from different angles to create shadows that highlight features.

-

Transmitted lighting: Shines light from beneath the part to capture the profile or silhouette.

-

Strobe lighting: Used on our high-speed models to take crisp images of a part in motion, dramatically reducing measurement time.

Is it possible to measure a part that is not perfectly aligned on the stage?

Yes. Our systems are equipped with powerful software features that allow for easy part alignment. You can use a "2-point" or "3-point" alignment function to automatically create a coordinate system based on your part's features, eliminating the need for tedious manual alignment and saving you valuable time.

What if I need to measure a part with both 2D and 3D features?

Our top-of-the-line vision systems offer a multi-sensor solution. They can be equipped with a high-resolution camera for non-contact measurements and an optional touch-trigger probe for contact measurements. This allows you to measure both a part's intricate 2D geometries and its 3D features, such as deep pockets, on a single machine.

Complete Section M

Complete Catalog US-1006

For all your Vision Measuring System needs

Comprehensive Services & Support

Training & Education

Comprehensive training on proper use, maintenance, and advanced measurement techniques.

Enhanced Services

Mitutoyo offers extensive hands-on expertise with contract inspection and contract part programming services to optimize your production and quality control processes. These Enhanced Services are idea for boosting productivity or adding expert help for projects large and small.

Field Service

Whether you need immediate repair service for critical tools or A2LA Accredited calibration that’s traceable to NIST on your measuring instruments, highly skilled Mitutoyo technicians provide fast, accurate and dependable service to keep you measuring with confidence.

E-Learning

Learn at your own pace! Enroll in Mitutoyo eLearning and get extensive hands-on training on our tools and software, including MCOSMOS C1 (STC-100 v5) and MCOSMOS-M1 (STC-101) courses.

Quality You Can Trust

Expert Support

Technical specialists available to help with your needs at a momentss notice.

ISO 17025 Accredited

Our calibration laboratories meet the highest international standards.

Industry-Leading Warranty

Comprehensive coverage backed by our commitment to quality.

NIST Traceability

All calibrations are traceable to national standards.

Ready to Upgrade Your Measurement Capabilities?

Connect with our experts to find the perfect small tools solution for your needs.