.webp)

Contour Measurement Made Simple with a 25% discount

Simplify profile measurement and accelerate inspection cycles with the Mitutoyo CV-2100M4 Contracer, a high-resolution, motorized contour measuring system that brings speed, accuracy and intuitive software together in one complete package. Now offered at a special promotional price through September 30, 2025.

CV-2100M4: Engineered for Excellence

Power Meets Precision

Whether you're working with cams, gears, turbine blades, or injection molds, the CV-2100M4 automates your contour inspection process to deliver faster throughput and more reliable results. With motorized operation, high-resolution detection and the powerful Mitutoyo FORMTRACEPAK analysis software, the CV-2100 system reduces inspection time, boosts operator efficiency and ensures consistent, traceable output.

Includes everything you need to get started: PC, monitor, software, and certified calibration artifact.

Better Throughput:

Set up times are reduced thanks to a smooth up/down mechanism with fine feed control for positioning the detector unit vertically.

Faster Speeds:

Experience reduced setup times with positioning speeds reaching 20mm per second, enabling swift and efficient part handling

Precision:

The ±45° tilt capability of the detector head enables accurate measurement of difficult profiles like sharp steps and steep transitions.

Ready to Experience the CV-2100M4 for Yourself?

Discover the remarkable speeds, precision, and throughput today!

Larger 2.8-inch Touchscreen

The bright, high-contrast display ensures clear visibility in various lighting conditions, while touch, swipe, and flick functionality streamline operation for quick measurement setup and data review, even when wearing gloves. For added convenience, the touchscreen can be disabled when needed, allowing for operation via physical buttons.

New HOME Key

The new HOME Key enhances user efficiency by providing one-touch access to essential functions and frequently used calibration and measurement conditions. This streamlined operation reduces setup time, improves workflow, and ensures a more intuitive user experience, especially in fast-paced manufacturing environments.

Compatible with new standard ISO 21920

The Mitutoyo SJ-220 is fully compatible with the latest ISO 21920 standard, ensuring its measurements align with the most up-to-date global surface roughness evaluation criteria. By supporting this standard, the SJ-220 provides greater consistency, traceability, and compliance for industries requiring the highest levels of quality control.

Increased Efficiency

The SJ-220 now has the ability to transmit measurement data wirelessly and display results and setting conditions with the optional U-WAVE-TIB. By attaching the optional wireless communication unit, it is possible to have wireless communication via Bluetooth® with a device (PC or smartphone) on which the dedicated app* is installed.

Smart Software

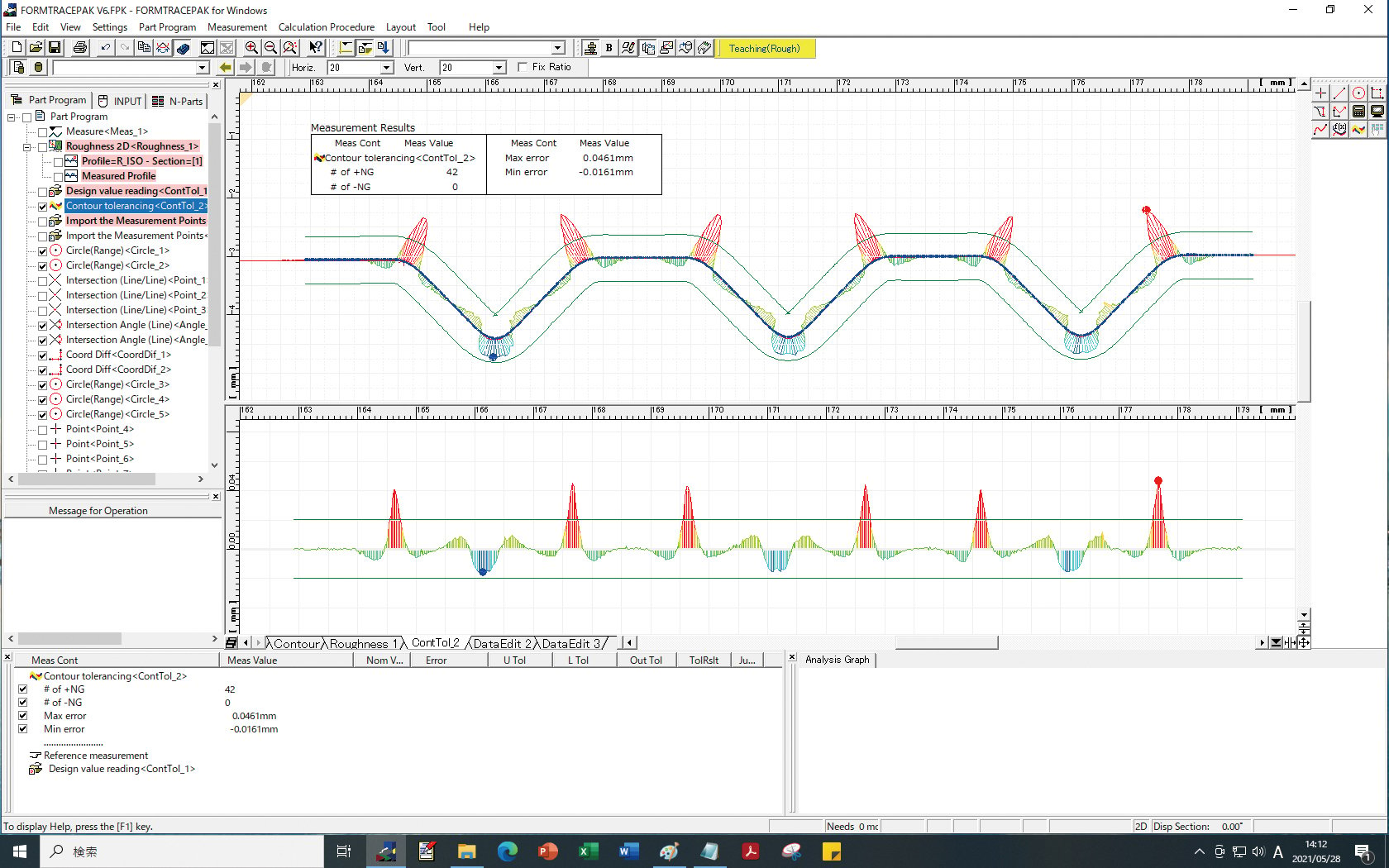

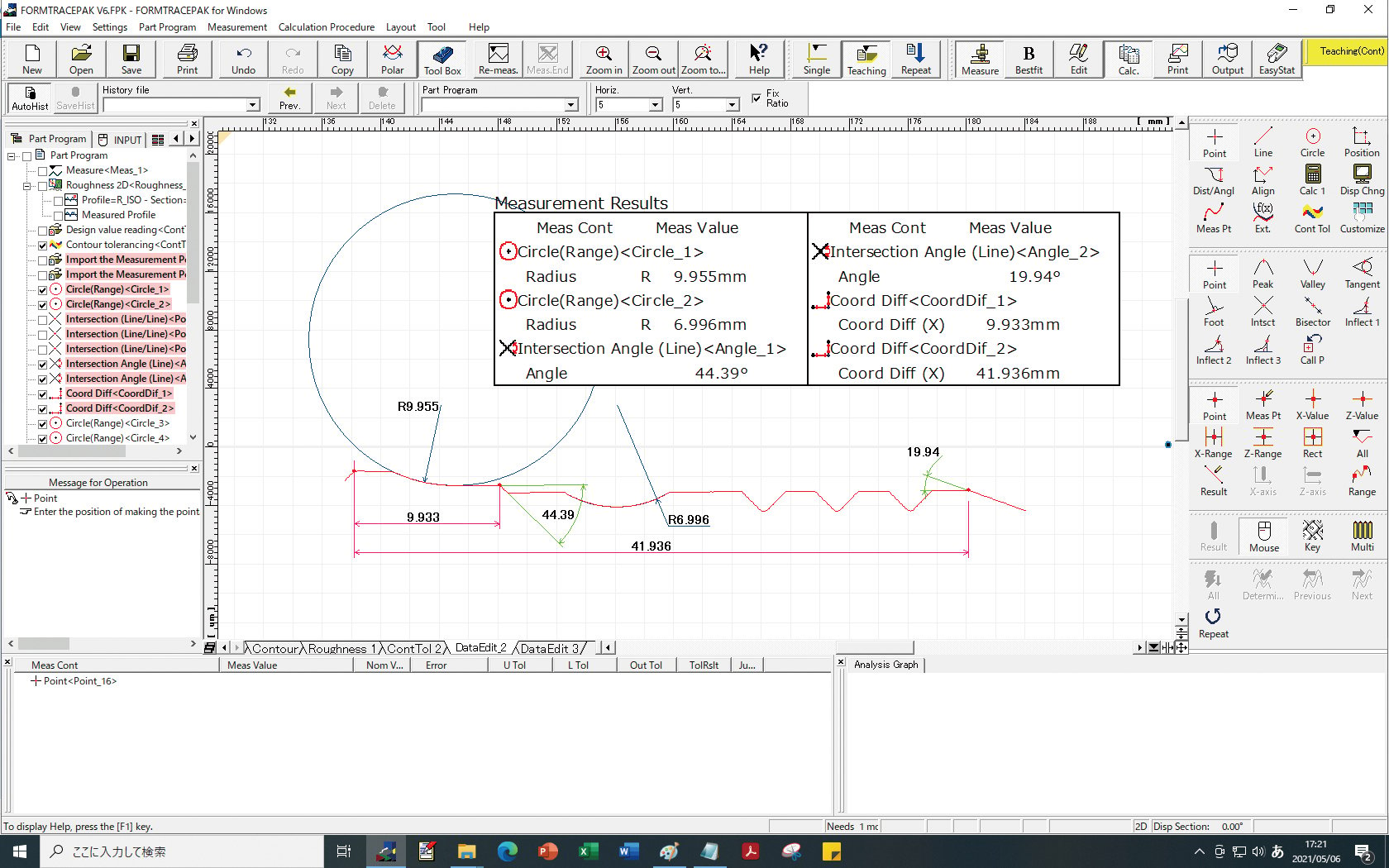

The CV-2100M4 comes equipped with powerful Mitutoyo FORMTRACEPAK software, which streamlines the contour measurement process through intelligent analysis tools and automation. Users can overlay measured profiles directly onto 2D CAD models for quick visual comparison, apply digital tolerances, and perform detailed contour evaluations without needing separate programs or manual interpretation.

FORMTRACEPAK also features Go/No-Go tolerance judgments with clear visual alerts, helping operators quickly identify out-of-spec conditions and make faster decisions on the shop floor. To support traceability and reduce administrative time, the software automatically generates comprehensive inspection reports in PDF, CSV, or DXF formats as well.