Measurement Versatility & Accuracy That’s Flexible & Easy to Use

The MiSTAR series of shop floor CNC CMMs delivers the toughest shop floor operating condition capabilities with the widest temperature accuracy guarantee with incredible accuracy, and it is now available in two sizes: the 555 and 575.

MiSTAR fits where others can’t — find out how.

The MiSTAR Series

Accuracy Where You Need It

Making Measurements In Harsh Shop Floor Environments Possible & Reliable

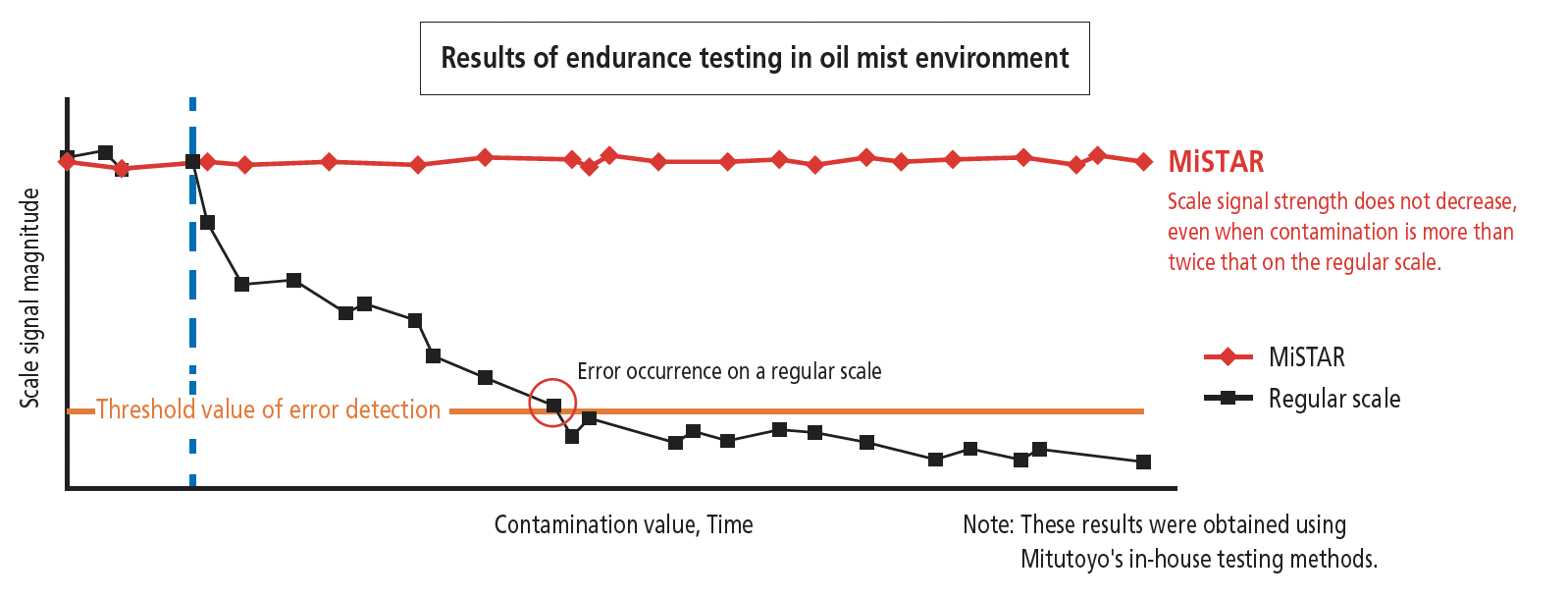

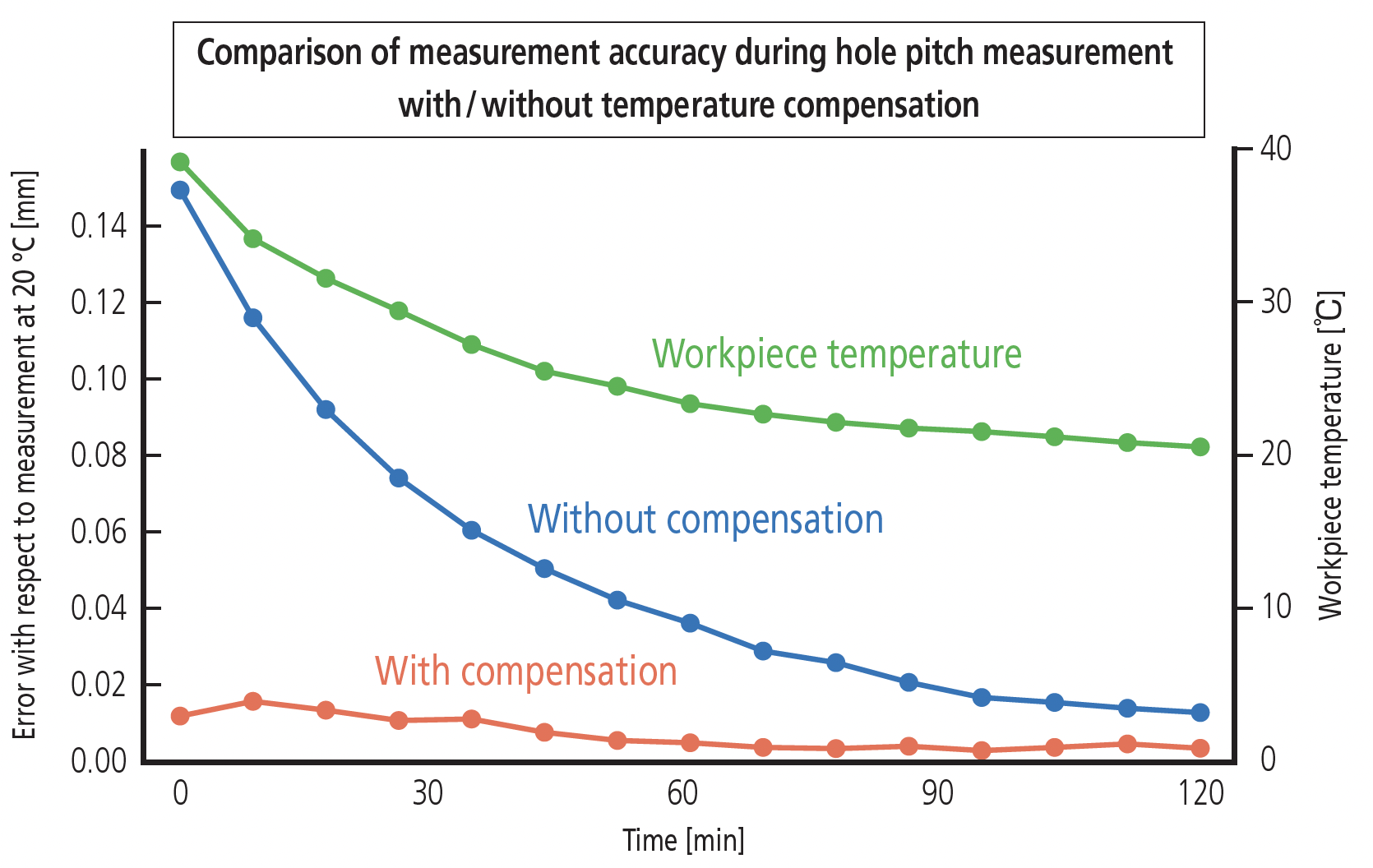

The environmentally resistant Mitutoyo ABSOLUTE scale and carefully designed structure of the MiSTAR CMM drives its contamination resistance and reliability on the shop floor. Advanced real-time temperature compensation technology guarantees accuracy over a wide temperature range with a length measurement error of just MPE of 2.2 + 3L/1000 μm*2, the best on the market.

Precision starts with a conversation. Contact us today!

What's the Best Fit?

Explore the MiSTAR Lineup

| 555 | New Product! 575 | |

|---|---|---|

| Single Button Operation | ||

| Measuring Range X | 500mm | 500mm |

| Measuring Range Y | 500mm | 700mm |

| Measuring Range Z | 500mm | 500mm |

| Footprint |

1.26 m² |

1.49 m² |

Got questions? Let’s make precision simple.

Purpose-Built. Feature-Rich. Proven Performance.

Compact Design

MiSTAR CMMs feature a smaller footprint, about 70% the size of conventional CMMs.

Two Sizes Available

The MiSTAR 555 has a 500mm Y-axis range; The MiSTAR 575 has a 700mm Y-axis range.

Superior Flexibility

The MiSTAR Series does not require compressed air, and plugs into ordinary 120V outlet; use it where you need it.

Wide Temperature Range Guarantee

The accuracy-guaranteed temperature range of the MiSTAR is 10˚C to 40˚C, the best available.

Simple Operation

The MiSTAR Series is equipped with Quick Launcher that enables simple, intuitive operation.

Improved Efficiency

Three-sided open architecture provides ample measuring ranges and easier placement of workpieces.

Measure With Accuracy & Trust Almost Anywhere

The Mitutoyo MiSTAR CNC Coordinate Measuring Machines merge cutting-edge technology with practical shop-floor functionality, making them a top choice in the Mitutoyo CMM lineup. Their contamination-resistant linear guide design ensures minimal maintenance in production environments, while a wide accuracy-guaranteed temperature range (10–40°C) eliminates the need for strict climate control. The MiSTAR Series of CMMs is engineered to boost productivity and maintain measurement consistency where it matters most: right on the shop floor.

Frequently Asked Questions

How easy is it to load and measure parts on the MiSTAR?

The MiSTAR is designed for effortless part handling. Its three-sided open architecture makes loading and unloading workpieces easy, while Mitutoyo’s clamping tools and pallet receivers allow for fast setup and quick measurement of similar workpieces — streamlining your inspection process.

What makes the MiSTAR more resistant to contamination compared to other CMMs?

The MiSTAR is equipped with a newly developed Mitutoyo absolute scale, which is highly resistant to contamination — making it over 2 times more resilient than conventional CMMs in tough production line environments. This helps maintain accuracy and reduces maintenance needs.

How does the MiSTAR handle temperature variations on the shop floor?

The MiSTAR is built for real-world conditions, with an accuracy-guaranteed temperature range of 10°C to 40°C. Its symmetric structure, uniform material selection, and advanced temperature compensation technologies ensure reliable measurements even when conditions fluctuate.

Where can the Mitutoyo MiSTAR be installed?

The MiSTAR is designed for maximum flexibility — it can be installed in-line, near-line, or on any size shop floor. Thanks to its space-saving design, single-support moving bridge, and built-in controller storage, the MiSTAR has a footprint approximately 30% smaller than conventional moving bridge CMMs.

How does the MiSTAR Series simplify the measurement process?

The MiSTAR Series features a single-button operation using the Quick Launcher, making part program execution simple and intuitive. The touch panel monitor adds to the ease of use, allowing anyone to run part programs effortlessly.

Does the MiSTAR support a motorized probe head?

Yes. The MiSTAR CMM supports motorized probe heads, including the PH20 and PH10MQ. The PH20 enables fast, accurate tactile measurements with rapid head movements, while the PH10MQ supports tactile and scanning probes and has 720 programmable positions, effectively making the MiSTAR a 5-axis system.